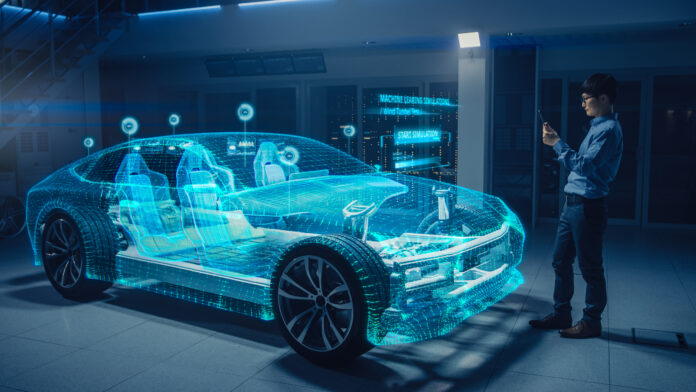

The automotive industry, known for its innovation and automation, is taking another significant leap forward with the integration of augmented reality (AR) into its maintenance processes. Augmented reality maintenance is changing the way automotive manufacturing facilities conduct inspections, repairs, and maintenance tasks.

The Fusion of Augmented Reality and Automotive Maintenance: 4 Critical Impacts

Augmented reality is a technology that overlays digital information onto the physical world, providing real-time insights and data. In the automotive industry, AR is being used to enhance maintenance operations in several ways:

1. Remote Assistance and Collaboration

One of the key advantages of AR in automotive maintenance is the ability to provide remote assistance and collaboration. Technicians on the factory floor can wear AR glasses or use mobile AR apps to connect with experts located elsewhere, whether they are within the same facility or even in different parts of the world. This real-time connection enables experts to guide on-site technicians through complex maintenance tasks, reducing downtime and errors.

2. Interactive Work Instructions

AR-based work instructions provide step-by-step guidance for maintenance tasks. Technicians can access these instructions through AR glasses or mobile devices. This interactive guidance improves efficiency, accuracy, and safety by ensuring that technicians follow the correct procedures.

3. Equipment Diagnostics and Data Visualization

AR can overlay diagnostic information onto physical equipment. For example, when a technician looks at a piece of machinery through AR glasses, they can see real-time data on its performance, temperature, or any potential issues. This enables predictive maintenance, allowing technicians to address problems before they lead to breakdowns.

4. Facility Layout and Mapping

AR can assist maintenance teams in navigating large manufacturing facilities. By overlaying digital maps and markers on their field of view, technicians can quickly locate equipment or components that need maintenance.

Benefits of AR Maintenance in Automotive Manufacturing

The integration of AR into automotive maintenance offers several benefits:

- Reduced Downtime: AR-based remote assistance and guidance reduce the time required for maintenance tasks, minimizing production downtime.

- Enhanced Efficiency: Technicians can complete tasks more efficiently by following AR-guided procedures, reducing errors and improving overall quality.

- Improved Training: AR is a valuable tool for training new technicians. They can learn by doing, following AR-based instructions in a hands-on, interactive manner.

- Cost Savings: By addressing maintenance issues proactively and preventing breakdowns, AR maintenance ultimately saves costs associated with repairs and downtime.

Real-World Applications

Several automotive manufacturers are already reaping the rewards of AR maintenance:

- Porsche: Porsche uses AR glasses to assist technicians in diagnosing and repairing vehicles. Technicians can overlay repair instructions and 3D models of components, making the repair process more efficient and precise.

- BMW: BMW employs AR glasses for quality control in manufacturing. Technicians use AR to inspect vehicle surfaces for imperfections, ensuring a flawless finish.

- Ford: Ford utilizes AR in assembly line maintenance. Technicians wear AR glasses to access assembly instructions and perform quality checks, improving both speed and accuracy.

Future of AR Maintenance in Automotive Manufacturing

As technology continues to advance, the future of AR maintenance in the automotive sector holds even more potential. We can expect:

- Wider Adoption: More automotive manufacturers will adopt AR maintenance as the technology becomes more accessible and cost-effective.

- Integration with IoT: AR will be closely integrated with the Internet of Things (IoT) to provide real-time data on equipment and component status.

- Enhanced Data Analytics: AR maintenance will offer advanced data analytics for predictive maintenance, helping automotive manufacturers further reduce downtime and costs.

- Improved Training: AR-based training programs will become more sophisticated, ensuring that technicians are well-prepared to tackle maintenance tasks.

Augmented reality maintenance is reshaping the landscape of automotive manufacturing. Its ability to enhance efficiency, reduce downtime, and provide real-time data is revolutionizing the way maintenance tasks are conducted. As the technology continues to evolve, it is poised to play an even more significant role in the automotive manufacturing industry, setting new standards for maintenance excellence.