The manufacturing landscape is undergoing a revolution fueled by digital technologies. The rise of smart factories is changing the way products are made, ushering in an era of efficiency, customization, and connectivity. In this article, we delve into the concept of smart factories, exploring how digitization and automation are reshaping manufacturing processes, enhancing productivity, and paving the way for a new industrial era.

The Genesis of Smart Factories

The Fusion of Digital and Physical Worlds

A smart factory represents the convergence of digital technologies and traditional manufacturing processes. It leverages the power of the Internet of Things (IoT), data analytics, artificial intelligence (AI), and automation to create an interconnected ecosystem within the manufacturing environment.

The Pillars of Transformation

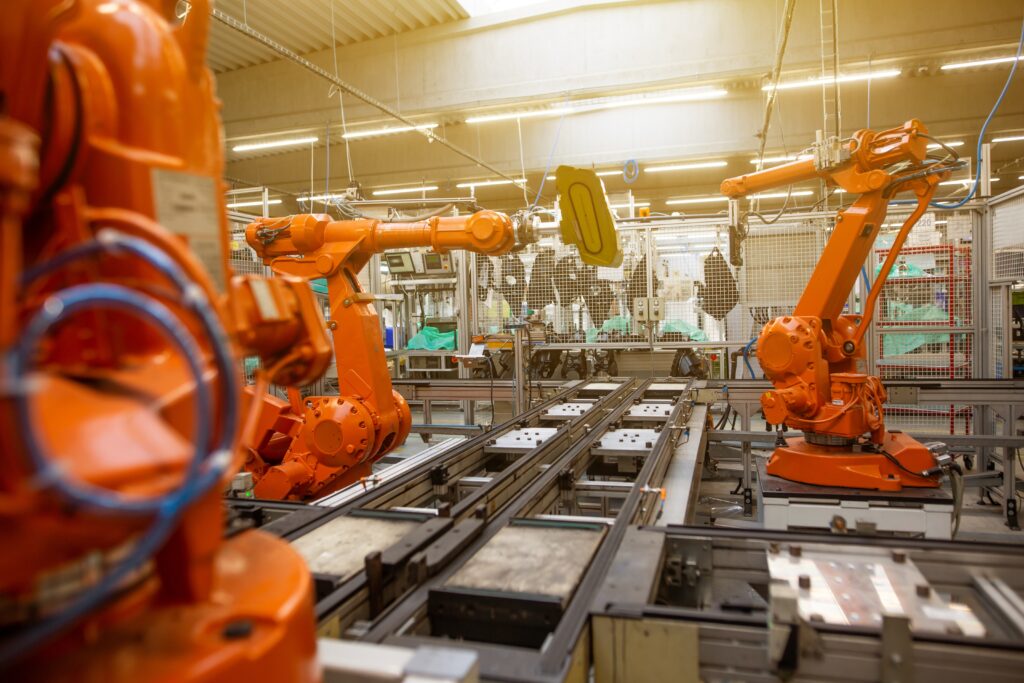

Smart factories are built on several pillars, including real-time data collection, predictive analytics, machine learning, and advanced robotics. These pillars work in harmony to optimize production, streamline operations, and respond rapidly to market demands.

Transforming Manufacturing Processes

Enhanced Connectivity

IoT-enabled sensors and devices are embedded throughout the factory, collecting real-time data on machine performance, energy consumption, and production metrics. This data is transmitted to a central platform, providing insights that drive decision-making and process optimization.

Predictive Maintenance

Smart factories anticipate maintenance needs through predictive analytics. Sensors monitor the condition of machinery, detecting anomalies and signs of wear. This enables manufacturers to schedule maintenance before breakdowns occur, minimizing downtime and reducing costs. General Electric (GE) has implemented predictive maintenance in their jet engine production, ensuring aircraft engines remain in peak condition.

Efficient Resource Utilization

Automation and data-driven insights optimize resource allocation. Whether it’s energy consumption, raw material usage, or labor allocation, smart factories ensure that resources are utilized efficiently, reducing waste and enhancing sustainability.

Advantages of Smart Factories

Heightened Efficiency

Automation eliminates manual bottlenecks, reducing production cycle times and enhancing overall efficiency. Predictive analytics prevent unplanned downtime, further boosting productivity.

Customization at Scale

Smart factories enable mass customization by seamlessly adapting production lines to accommodate different product variations. This agility meets individual customer demands without sacrificing efficiency. Adidas employs 3D printing and automated knitting machines to produce personalized shoes tailored to individual customer preferences.

Quality Enhancement

Real-time data monitoring ensures consistent product quality by identifying deviations and defects early in the production process. This leads to fewer defects and enhanced customer satisfaction.

Workforce Empowerment

While automation handles repetitive tasks, skilled workers focus on complex problem-solving and innovation. This enhances job satisfaction and overall workforce productivity.

Overcoming Challenges

Data Security

The influx of data in smart factories requires robust cybersecurity measures to safeguard sensitive information and prevent potential breaches.

Skills Gap

The transition to smart factories demands a skilled workforce capable of managing and maintaining advanced technologies. Addressing the skills gap is essential for successful implementation. To bridge this gap, companies like Siemens collaborate with educational institutions to train the next generation of skilled technicians.

Integration Complexity

Integrating legacy systems with cutting-edge technologies can be complex and requires careful planning and execution.

Navigating the Future

The advent of smart factories is not just a technological shift; it’s a cultural transformation that redefines manufacturing paradigms. As digitization and automation reshape the factory floor, the focus shifts from reactive to proactive, from traditional to innovative.

The future promises an interconnected ecosystem where machines, data, and human expertise collaborate seamlessly. Smart factories lay the foundation for an agile, efficient, and responsive manufacturing sector—one that’s poised to meet the challenges and opportunities of an ever-evolving global market.